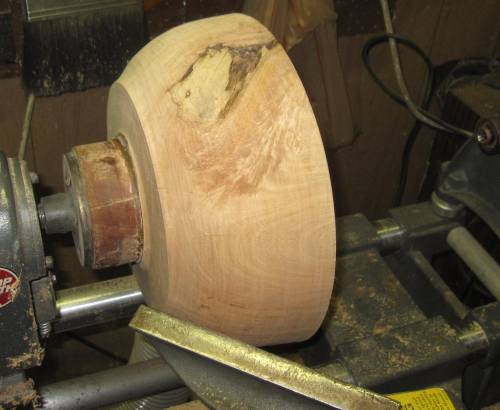

One year ago my three large bowl blanks were in a rather primitive state.

One year later, it is time to get around to bowl blank #2.

Could have got to it much sooner but winter set in.

The bowl blank is a little out of round and there is a lot of mass to work with. A gear reducer is called for.

What I like to do is find the low spot and scribe a heavy black line with a magic marker.

100 RPM is the slowest speed on the Shopsmith. Start the lathe and increase speed until you pick up vibration

and then back the speed off a bit.

It only takes a few minutes to bring the bowl blank back to round.

There is too much material here for a salad mixing bowl so I'm going to trim some off and use the excess for a matching plate.

The parting tool is used to score a groove about 1/2" deep.

The groove serves as a guide for my poor man's band saw (total cost: $8.00). Works rather well, by the way.

Turning speed is probably @ 250 rpm. Move the saw back and forth slightly so the teeth don't overheat.

The process doesn't take very long. 10 minutes gets me almost through.

There! The cut is very smooth and I am not going to waste much material at all.

The trimmed down bowl blank has a much better looking profile.

There is still a lot of meat to deal with so in the interest of saving time, I'm switching to a power tool.

I absolutely love my 4" chainsaw blade for removing lots of material quickly.

Eight minutes later, I have this roughed down to size. Note the divot at the top of the photo.

It is easy to get too aggressive with this particular tool.

You can also use the chainsaw attachment to take a lot of meat out of the inside of the bowl.

Don't use it whilst the blank is turning or you will see results like this.

The bowl blank has to be static. I am testing out another tool for the inside so that's it for the chainsaw blade.

Cleaning up the outside of the bowl was not much of a problem but I could not spin this at 600 rpm

without experiencing severe vibration. This was somewhat puzzling because the round was well, round.

Turns out I have a bit of a problem with rot. Judging from the balance problems, it must be significant.

This is a Bedan Tool. A couple months ago I was looking for a tool with which I could hollow our a number of small blanks quickly.

It did an admirable job and saved me a lot of time. I though in lieu of the chainsaw blade, this would work well.

It didn't. I think the reason was the turning speed was too low. The tool definitely works at 600 rpm but not so well at slower speeds.

I'll give this another shot when I can crank the speed up.

I don't think this is going to take that long anyway. Other than the balance problem, turning starts out well.

This area is going to be the problem child. Keep a good grip on your turning tool of choice when dealing with something like this.

What happens is the tool will dig into the rotted area quickly, causing a divot. The tool then hits the divot and bad things happen.

It is easy to do when turning at slower speeds but the problem is reduced by making less aggressive cuts.

There us still a little original wood holding the rim together but it needs to be reinforced.

I use a little thin CA glue so that it soaks in, and then use a bit of gap filling CA glue.

I don't want the rim to separate while turning and will probably look at a partial inlay soon.

This really isn't too bad.....as long as the rim stays together.

This is turning well. However, I'm good for about an inch a day..

The rotted area should not get much bigger than this. It's still manageable.

I'm getting kind of tired of this - time to whip out the chainsaw tool and get rid of some material.

The Shopsmith really isn't designed for handling large bowl blanks. It is too light weight.

You can buy a kit which adds 30-40 pounds of weight to the machine but it really isn't enough.

Slow speeds and big bowl blanks = a long time.

Ten minutes later, I am well past most of the rot. I did manage to ding the bowl edge.

I've gotten pretty good at peeling out the excess smoothly.

It doesn't take much to true up the inside anymore.

This is a very odd sized hole - much bigger on the outside than it is on the inside. I think I could use a second opinion on this one so I asked for some assistance from Jimmy (okiebugg200@cox.net) who lives in Oklahoma. I should post the answer as a standard Q&A for this kind of thing because it was useful:

First, use a magic marker to encircle the hole both inside and outside of the hole. Slather it on. It will help you later It makes the inlay more dramatic. Really paint all around the hole. Cut a piece of plastic (I use tackle box dividers) to roughly fit the hole in the inside of the bowl. . Trim the plastic with a rotary wheel using small rotary bits (with very light pressure to make it fit as exactly

as you can.

Next, put your pattern onto the bowl from the inside. Glue it in place with hot glue....comes out of a small dispenser that heats the glue and makes it reasonably malleable to glue the whole piece into place with about five minutes of working time. Before the repair panel is totally put into place, decide on how you want to inlay the outside vs the inside. Your plastic patch can be put on the wood on the outside of the inside of the turning. Patching on the outside of the inside will allow you to inlay the whole mess all the way to the plastic patch you built and glued on. If you’re going to use Turquoise, go to a machine shop and tell them you need small particles of brass and some brass dust...........I’ve done this before if you hadn’t figured that out already. If they make small particles, I add it to the project willy-nilly

Decide large or small turquoise pieces. A large stone is what draws the eyes. I buy large Nuggets and break down the worst looking of the lot I made a simple smasher out of a piece of 2x4 cut to 15” long. Use a boring bit....I generally drill my hole to a size that will accommodate my BFH.(Big frapping hammer). Don’t drill through it. Leave about 3/4” on the bottom of the smasher.

I epoxy a large flat washer to the bottom of the hole. You can then use large nuggets to make small ones and even dust. I take another round metal piece the same size as the first (it needs to be a solid piece of metal to be the smasher and keep the broken stones from flying all over the place. Over in your part of the country, you should find a wholesale Jewelry Supply that will sell to non-regulars. I have a supplier in Taos who cuts me a good deal when I buy 20 to 50 Lbs of nuggets.

If you have the patch in place, You can lay in all of the inlay from the outside of the bowl, remembering that you are also doing the inlay for the inside of the bowl at the same time, but all from 1 direction. Again, I use a dot of hot glue to each piece and set it in place. Setting with CA doesn’t work well because of the permanency created when using CA. The hot glue will allow you to make adjustments to the stones without tearing everything else up. Then once everything is placed, use thin CA to semi flood the area. I don’t use accelerant on a prize that size. I use of all things a cool mist humidifier set back about two feet, using just the mist. Water vapor will slowly cure the CA. After curing the thin stuff, I give it a lubricious coat of med CA and slow cure it again

The tedious part of doing that size hole is laying it in. Turn the bowl up on the side away from the hole and prop it so that it is comfortable to work on. Now comes the tedium of placing each nugget in a place where it belongs, remembering that once you de glue the plastic patch from the hole.......remove the patch and it will be inlaid from both sided

Sanding. If it is possible, I will use a rotary grinder (for welding) and carefully sand the Turquoise points down to wood level. This also helps to rid the project of the CA that has ran down the side

of the project Once it is all sanded, drink a beer for me and get to sanding on the lathe. If the Turq is still a little above the wood level, I use 100 grit on the Turq to bring it down

I hope my answer wasn’t too long and convoluted.

Anyway, I had trouble getting the plastic to fit right and the glue I couldn't spread thin enough without compromising the inlay. It did however give me an idea.

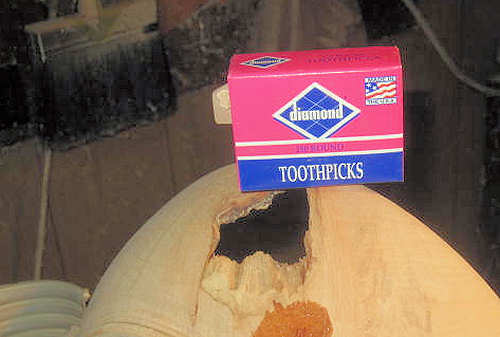

What about using toothpicks instead of plastic?

It's hard to tell from the photos just how wide the hole is and the toothpicks illustrate the width of the problem.

It was a large gap.

This does look more manageable.

I'm going to tackle the outside first, taping up the inside to minimize CA glue and malachite dust leakage.

Malachite is the inlay of choice. It looks good, it's cheap and it's soft. These strands are available for 3-4 dollars from Hobby Lobby stores.

I use a tall chili can and an arbor press to crush the stones. The tall can helps minimize flying malachite chips.

Boy, this is going to tale a lot of inlay.

Overfill the area with inlay.

This is going to require lots of thin CA glue. I'm taking my time doing this because I want the toothpicks get a layer over the toothpicks first. I suspect if I just filled it up, the leak-through would be pretty nasty.

The inlay is going to stay in this position overnight. A lot of glue and inlay has to set.

The following day I had a look at the other side and it didn't look too bad.

There are a few hunks of dried CA glue here and there but those are easily taken out with a scratch awl.

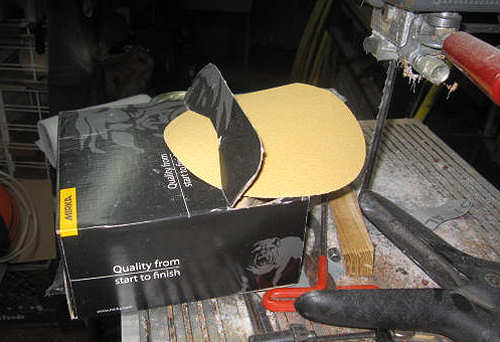

These 100 grit sanding disks from Mirka and available through Amazon are the disks of choice for knocking down inlay.

Only two disks were required to knock the malachite down. Note: the round is stationary.

I am pleased with the results. This needs filler material though, so clean the area and blow out the inlay so the gaps are clean and clear.

The second time around involves a finer layer of malachite dust and more CA glue.

Ok. The inlay is now flush enough to start turning and finish the bowl outside. The bowl outside will be finished to 400 grit and I'll buff the inlay itself to 600 grit.

The bowl outside is finished with tung oil - 2 coats.

Bowl Inside, first coat of tung oil.

The bowl turned out very well considering the extra aggravation involved.

Now for the matching plate

My this looks encouraging. I'm seeing some surface cracks. Maybe I can turn them out.

The round is turning down easily.

Turning isn't taking any time at all. I'm a little suspicious at that.

I tend to flip back and forth between turning the inside and outside, concentrating on getting the piece centered and the center of gravity as close to the headstock as soon as possible so I can crank up the speed.

There are a few small cracks to repair with sawdust and CA glue.

The Sorby adjustable scraper works well for bowls like this. Lot of cracks persist. I think it is because this bowl blank was nuked a little too much while green. The matching bowl looks fine but this piece cut off the end got too dry too fast.

The plate is soaking up CA glue like a sponge so there are two options....a spotty bowl or.......

Soak the entire thing, which is a good reason for buying the big bottles of Stick Fast.

All the CA glue seen here soaked through from the other side which means.......

Soak the other side with CA glue as well.

This is a handy tool for finding the low and high spots, particularly for convex and concave surfaces.

Not really applicable here but it is worth mentioning.

Wave sanding disks are ideal for this type of work. They don't dig into sloped areas like some of the others do.

The plate is sanded to 320 grit and any remaining cracks probably have a mixture of sawdust and white CA glue flecks in them.

Blowing out the cracks with compressed air will assist in a better finish.

Stick Fast from Woodturninz.com is a cost effective solution for those projects requiring lots of CA glue.

At this stage of the game a medium viscosity, gap filling CA glue is what is needed. Let this harden naturally.

After the third sanding, the surface looks nice. About time to get this off the lathe.

Something to consider is how you are going to sand the bottom once the piece is off the lathe. In this case I don't have a wide enough tool to remount the bowl.

An answer is to avoid cutting tight corners and instead make a nice, wide sloping cut which will make the sanding job look much more professional.

I use the parting tool to not only part, but also lightly clean up the bowl bottom at the same time.

A hand saw is used to finish cutting the plate off the lathe. Better to leave a little extra material on than to have the plate go flying off the lather.

Not bad. I can work with that.

Darn - the plate is just a little to wide to grab so this is going to be a manual effort.

Good thing I have enough CA glue left to balance out the finish.

I've got just a little extra CA glue around the edges but other than that, it looks ok.

The finished set, tung oil finish. The smaller bowl is the result of some experimental spalting I did a couple years ago.