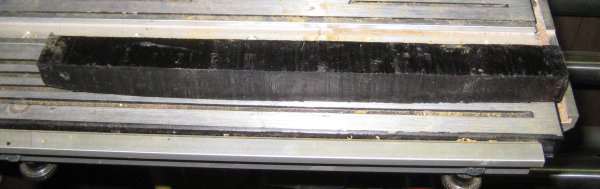

I picked up a chunk of ebony which may or may not still be green to use as a starting point.

Ebony apparently cracks when it gets too hot but is fairly easy to turn.

I was a bit more careful this time in my banksia pod selection.

Banksia pod blanks clearly need to be reinforced so I picked up a couple brass tubes which were sized for magnifying glass blanks, which should work considerably better than the original plan.

Just to be on the safe side, I took my time drilling out the ebony blanks.

A brass tube is going to support all of the banksia blank and go an inch or so into the ebony blank.

The ebony blank is not drilled all the way through - just enough to accept the remaining length of the brass tube.

Wood glue is used to glue the hair stick blanks together, and CA glue is used to glue the blanks to the tubes.

This should be much stronger.

However, the banksia part of the hair stick still needs strengthening.

The part the pin jaws are going to clamp on to is backfilled with sawdust and wood glue.

All holes where brass is seen are bridge with turquoise and CA glue.

I'll a day or two for everything to settle and we'll see what kind of hair stick can be derived from these humble beginnings.

Well, here we are two days later and ready to try again with the new, fortified hair stick blank.

This is turning fairly easily. A chunk of the banksia blank not fortified with a brass tube broke off,

but that had not affected anything. I think this is going to be a problem, though.

About 20 minutes later, I had to stop. The banksia blank broke again just below the pin jaws, where the red hairs are.

I glued that back together with wood glue and am going to have to stop for the night.

This will resume after a couple days when the weather gets off those sub-zero temps.

Looking a bit into finishing ebony, I found this on one of the wood working forums. Makes Sense:

Ebony is an extremely oil wood and prone to cracks when heated from drilling or using a friction polish or any finish that creates heat

(CA finishes create heat).

The big secrets to making ebony pens that do not crack is drilling at low speed and in small increments...

I generally clear chips on ebony every 1/4" of drilling and allow the bit to cool a bit before drilling again...

As for finishing ebony... sanding creates heat, so sand gently and allow the blank to cool often....

I do not use any finish on ebony... I wet sand it to 12000 grit MicroMesh and leave it alone...

The oils in ebony will impart a beautiful patina to the pen from the natural oils and the oils in the hand of the eventual user..

Using the above techniques, I have never had an ebony pen crack...

I am also thinking that if issues continue with the banksia pod blank cracking, perhaps I should fully support the blank with brass and

then use a suitable pen cap to finish the top. This might be a better approach.

Got in a bit of a hurry.................

That's why I make spares.

These kinds of temps should help the Ebony stay cool.

This is looking pretty good - total time so far, about 45 minutes.

.......................Brass Tube showing through.......................

I'm about done with these fricking hair sticks, unless I come up with an option C.