Lots of room, no lack of space.

It's rounding nicely, turning at a medium speed.

A crack showed up in the ebony. I don't think this is heat related. It looks like it was buried. It may turn out.

If it doesn't, I won't be overly surprised.

So far so good. The crack is getting smaller.

I am starting to run into a slight problem. With banksia, you want to turn at high speeds.

Slower speeds can cause the tool to catch on the banksia pod seed 'lips', tearing up the blank.

Also, the holes are growing larger and there is no brass tube in this one. I am reinforcing the holes with

Stick Fast, my new favorite CA glue and am going to have to crank up the speed.

The crack in the ebony blank is just about turned out. The banksia is turning down ok but the tool is

starting to catch. I'm adding more CA glue to all the joints and am letting this sit for half an hour.

I started picking up some vibration and then the sacrificial block on the tail end flew off for parts unknown.

That's ok though, because I still have a lot of meat left on the ebony and the crack turned out - one less joint to fail.

I will re-chuck this and continue on.............

............ggggggggggggggggggrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrrr................words that are polite to print fail me.

The banksia pod blank split in two. It and the ebony flew off the lathe. The ebony blank however, is in one piece.

Pardon me while I go down to the store and get a couple cold ones.

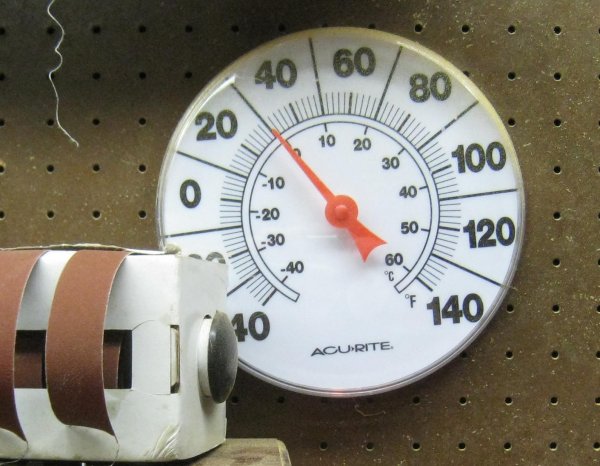

One day later, the temperature looks cool enough that heating up ebony is not going to be an issue.

The fricking hair stick is once again back in one piece.

The Paduak Hair Stick is 'normal' sized and since I am getting tired of this, I might as well go for broke and make a

really long one. I would think a hair stick going all the way through the bun would not be an issue if it was thin enough.

Odds of getting down far enough with this unlikely mix of woods I would say is about 70-30 against.

However, I have only a little bit further to go.

Helpful hint:

When you are doing inlay, ensure the groove you cut follows the taper of the wood. Otherwise when you start sanding, it is very easy

to sand out part of the inlay.

Lots of inlay and lots of CA glue - this will need to sit a bit.

It's still in one piece! Amazing........

I'm at the point now where I think I should finish this off by power sanding it down the rest of the way.

Time to put a preliminary finish on this while both ends are still supported. My usual method of finishing banksia will probably lead to disaster so I am opting for a BLO finishing variant.

Good enough for government work and certainly good enough for a hair stick.

I used a sanding disk to part the ebony side of the hair stick from the tail stock, turning at a slow speed.

Another coat of super secret finish.

Time to cut a design into the top of the stick and remove same from the lathe........

......and believe me, this is going to be nothing fancy.

This stick has no brass tubes in it for reinforcement. Therefore if this gets dropped on a hard surface the banksia end of the hair stick is likely to break. If the stick is used to twist hair (I don't know if hair stick users do that or not), odds are it will break.

The stick should be for ornamental use only. Anything else, it will probably break.

I think in retrospect I was on the right track when coming up with the bright idea to use a brass tube, but I didn't measure accurately

enough. The brass tube should entirely support the banksia end of the stick up to solid material, and only go far enough into the ebony end to form a good, tight bond. The depth for brass insertion on the ebony end of the stick should only be 1/4" - 1/2" .

I would be more choosy as to how to cut the banksia blank in that the head end of the blank should be as solid as possible to help prevent catastrophic failure.

So if you are up for a challenge or feeling particularly masochistic, give a Banksia Pod and Ebony Hair Stick a try.