Flame Box Elder when properly finished is some pretty nice stuff.

The only place I've seen decent rounds are on Ebay and are sold green and waxed and at least 25% M.C.

In other words, one has to have a game plan for drying, as well as finishing.

Box Elder is not a true hardwood by any stretch of the imagination. It is soft like pine, and is best described as a 'punky' wood.

This round is 9.5" x 5.5", and has been sitting in an outdoor shed for about six months. During that time it didn't shed much weight at all.

I would have to say that this is about as large as one can go on a mini-lathe............

Tail stock support would be a really good idea.

It looks like the guide is going to have to be moved at some point - get half the piece round, remove the round, place the guide near the headstock and round the other half.

The 'Easy Rougher' makes rounding the blank an easy task. That and.........25%+ water.......

Step 2 - rounding the other half. Not much vibration at all, amazingly enough.

Sometimes it it looks nice to leave a little bark on but in this case, it is going to have to go.

30% Moisture Content! Cut off the tree and immediately sealed.

So far this has taken only 90 minutes or so, but it is getting late. If you're going to quit for the night, green rounds should be covered with wet rags and then placed in a plastic bag until ready for turning again.

If you don't, woods like box elder can crack out all over the place in a short period of time.

Day Two

A nice thing about green wood is that the chips fall pretty much straight to the ground - perfect for the apartment dweller.

Hollowing this piece of flame box elder only takes an hour or so. It is best to leave more meat on than one normally might before drying when dealing with soft, punky woods.

Drying

The bowl blank is then covered with denatured alcohol (1 gallon from Lowes is around $13.00) for several days. I am in no hurry.

The object is to displace as much of the water in the wood fibers as possible with denatured alcohol, letting miscibility work its magic.

The smaller chunks are rock maple, which should make for some nice pen blanks.

Three Days Later

The flame box elder blank is set outside to dry for several hours, removing the surface alcohol to the point that it feels not quite dry. It needs to be dry enough to reinforce the weak / problem areas.

It is a good idea to weigh the piece before drying, in addition to using moisture content meters.

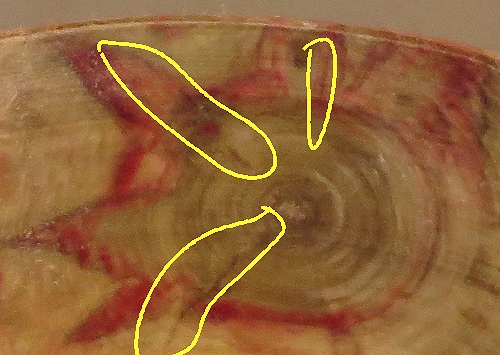

Bad things will happen if you don't reinforce cracks, heartwood and other imperfections prior to drying and for that..... we shall use:

CA Glue. Rather than buying those little 4oz bottles of CA glue for @ $12.00 or so, one can buy 16oz bottles of the Starbond brand (available from Amazon) for around $30.00. The thin CA glue is what we want to use.

Really let the CA glue soak in.

Coat both inside and outside areas where there are cracks and heartwood. I used about 2 ounces for this piece.

At this point the bowl blank is ready to be taped up for the final drying.

Tape up the outside of the bowl, leaving the inside open to the elements.

Store the blank in a cool area on a wire rack with the exposed wood facing down, the idea being that the compressive forces when drying will be inward rather than outward......which hopefully will reduce the chances of warping, cracking and so on.

It takes about 3 weeks for the moisture content of this once 30% + chunk of box elder to reduce to 10-12%.

Not bad at all!

Three Weeks Later:

The piece turned down rapidly and sanding is a breeze.

Here is an example of effective dust control and cleanup for the apartment dweller.

A. Cheapo 5 gallon Shop Vac from Walmart with a good filter purchased from Lowes.

B Vacuum Extension which mounts over the piece and is supported by a couple rubber bands and a high-backed chair.

C. 4' x 6' industrial floor mat from Staples which cost twice as much as the Shop Vac!

The Tru-Oil finish is dry and now it's time to remove the bowl from the sacrificial block.

The parting tool is the only traditional tool I have left and that is sharpened using a diamond file.

Finishing the bottom is a piece of cake.

A couple hours and one more coat of Tru-Oil to blend everything in.......this is looking nice.

Success!

On the right is another round I picked up a couple months ago with a lot more flame - 9.5 x 5.5.

Now that will make for a challenging project.

Closing Comments

1. Green rounds of flame box elder dries quickly after rough-turning and soaking in denatured alcohol but the wood is not all that stable.

Several rounds had spots where layers (for lack of a better term) would want to slough off when drying. For those, I coated the entire roughed out bowl with thin CA glue to reinforce the entire thing. Most areas suck in CA glue as a sponge would.

That is the reason for buying CA glue in 16oz bottles - you tend to use a lot of it.

2. CA glue can react with something in the wood, producing smoke. The smoke can set off smoke detectors and because of that it is best to apply the CA glue outdoors rather than indoors.

3. The more natural the better in that if there is a choice between natural stone pebbles and crushed stone pebbles, go with the natural stone.

4. There are usually a number of cracks that have to be filled so save some sawdust. The cracks are generally small and irregular. They fill easily and with a finish that darkens the wood (like Tru-Oil), the filled areas are very difficult to spot, even with a trained eye.

5. When power sanding the outside of the larger rounds, tail stock support is pretty much a necessity if you want a smooth finish. I keep a couple spare bowl blanks of various sizes for this purpose.