Turning pens from deer antler is not much different from turning pens from anything else but there there are a few considerations I could pass along for turning that perfect deer antler pen.

The first thing to determine is what size pen do you have in mind? While it may seem obvious, a larger pen requires a larger piece of antler. The pens used in this demonstration are the 'Mesa' kits from Woodturningz.com. These are similar to Woodcraft's 'Wall Street II' pens.

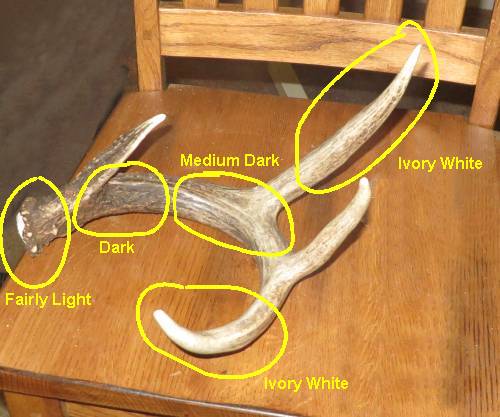

A friend of mine brought this nice White Tail shed from northern Canada and it will fill the bill.

Note: Antlers from recent kills should be set aside for several months so blood, capillaries and the like in the antler can dry out.

Size can also be a determining factor on the color you want the deer antler pen to achieve.

Say for example you want an Ivory White Deer Antler pen. The antler tips have to be wide enough in diameter and long enough to accommodate that.

Here are a few examples, turned from the above image. Deer antler is a low-grade ivory and a pure white pen can be fairly desirable to some. To me, it looks more like plastic at first glance.

Cutting the Antler Down to Size

A cheapo scroll saw with a raspy blade from Ryobi works fine for me.

Deer antler cuts quickly and easily. It only takes a few minutes.

It looks like I can get some Mesa pen blanks out of at least four of these.

Drilling

Drilling deer antler can be a challenge. What works well for me is using a set of pen blank drilling jaws, slow speed, light pressure and patience.

I generally try to position the blank off-center so as to pick up some of the lighter colors found just under the 'skin' of the antler. This produces some nice results.

Now for the new, improved safer way to use a pen mill:

You use the Tail-stock Hand wheel to turn the Tail Stock Spindle into Pen Milling Power Assist Tool,

using a wrench or a pair of channel-locks to prevent the blank from spinning.

This is a much better option than using your hand.

Ever tried milling something really hard, like snake wood or iron wood?

Using this method, milling the blank ends is a piece of cake.

Should have thought of this a long time ago.

It's always good practice to seal the ends one more time with CA glue.

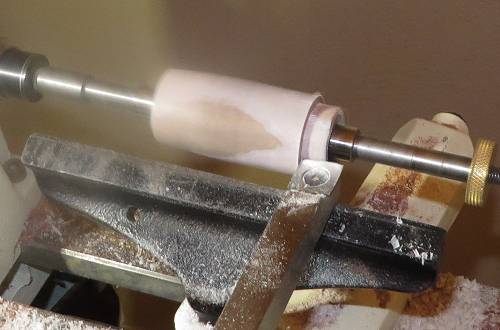

Turning

The object now is to turn the deer antler pen blank round of course and for that, I am using the Easy Tools CI0, full-sized tool. For finishing, the smallest (and cheapest) Easy Detailer works just fine.

A few notes about these tools:

1. The guard needs to be set further back than where one would set it for conventional tools so as to have full contact with the flat bottom of the tool.

2. If there is a high and low end, start with the high end and work across from there.

3. Square tools are pushed or pulled from side to side into the material. Don't push them in.

The exception is the square bit with a slight radius. It can be used to knock down high spots.

Remove the high spots first.

You can be much more aggressive once the high spots have been removed.

The inner portion of this section of antler blank will end up being textured if you will, even when sanded.

A coat of medium CA glue will take care of the divots.

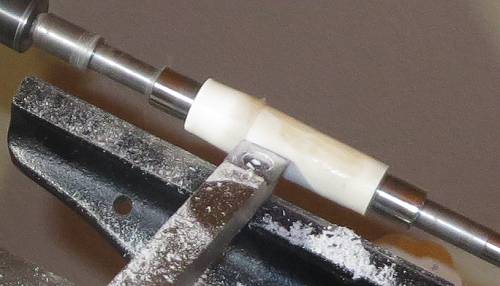

This blank is almost finished. Needs a little touch-up on the ends but otherwise looks good.

This piece was cut much higher on the rack and I would expect it to be much whiter in color

With a little luck, this deer antler blank may turn almost white!

Totally white except for one small spot and that can probably be sanded out.

Since this is for all intents and purposes pure ivory, no CA glue is required.

Sanding with Micro-Mesh will put a lustrous shine on ivory.

Dealing with the Tougher Pieces Safely

The base of the antler can produce decent results but it should be drilled first, rather than cut to size

because cutting to size first has the high probability of being cut to short.

Pen blank jaws only work marginally well for this sort of thing so it is best to go slow and ensure you wear safety glasses.

To figure out exactly what I can use, I prefer to mount the drilled piece of antler on the mandrel sans brass tube.

The object is to get the antler blank round so it can be cut to size safely and accurately.

This way, the antler blank will not fly off the lathe and nail something or someone nearby.

Antlers are hard and can leave a nice welt on say......the forehead.

If using Easy Tools, select the square tipped one with a light touch until the antler blank is more or less round.

This is about ready for the pen mill.

Pen Milling the Easy Way - little physical exertion required.

Finished Results

'Mesa'

'Duchess'

These three pens had to be finished with CA glue and came from the base of the antler.

'Black Mesa'

This pen blank is pure ivory and is from a large prong on a good-sized deer antler.

No CA glue finish required.

Finished with EEE and micro-mesh.

'Copper Cigar'

Pieces from the middle of the main rack were used for this cigar pen.

Closing Comments

The hardest thing about turning pens from deer antler is figuring out how to cut and drill the blanks.

Once you have a handle on that, the rest is a piece of cake.

A scroll saw or band saw is a good, safe way to cut deer antler.

There are individuals who will pre-drill deer antlers cut them to size for a fee if drilling them yourself is a problem.

If you end up going that route, ensure you tell them where on the antler you want the blanks taken from.

The overall color of the pen is determined in large part from the size of the deer antler, where the blanks are cut and how they are drilled.

The larger the antler, the more of a color difference between the 'marrow'' and the outer layers.

For a good color contrast, drill the antler blank off-center (not hard to do.......they usually mount off-center anyway).

If the rack is from a fresh kill, let it sit for several months before using it.

Well, enough said about turning pens from deer antlers.

Have Fun!