Late in the summer of 2013 c I accumulated 25 or so green bowl blanks from various vendors off of Ebay, just about all cut fresh off the tree and sealed using AnchorSeal or Paraffin.

The advantages in turning green wood are:

1. Cost - Price + Shipping is usually lower than buying a dry round (assuming you can find one).

2. Ease in turning - not as hard on the tools.

3. A lot less dust and if you are doing this in an apartment, this is a biggie.

The disadvantages of green wood are:

1. Warping

2. Checking

3. Splitting

4. Cracking

5. Shipping Costs

6. Drying Time

7. Storage Space

Helpful Buying Hint:

Buy your rounds in the fall as temperatures start to cool off. If stored outside the colder the weather gets, the slower the rounds lose moisture and the less likely they are to start cracking out.

Moisture Content (MC) frequently runs + 20% if you purchase one of these rounds, meaning that many of

these waxed and sealed pieces were quite literally freshly cut off the tree.

Waxed and sealed does not do a lot of good if the round contains heartwood or significant amounts of rot,

which is frequently hard to spot when looking at photos of a waxed round. It does not take long for these

rounds to start cracking regardless of how much sealant has been applied.

Hackberry

Prior to this, four rounds were turned and soaked in Pentacryl to see how that worked out.

This time around I am trying denatured alcohol, available at Walmart for about $6.00 a quart.

I will also be using a lidded plastic bowl, also from Walmart which cost about $6.00 as well.

From what I gather, a molecule of alcohol is smaller than a molecule of water and alcohol has

an affinity for water and it utilizes the property of miscibility, which more or less means water and alcohol mix together well.

And, I found a Solvent Miscibility Table!

So, if wood is soaked in alcohol for a period of time, alcohol will penetrate the wood, replacing

water in the wood with a solution of water and alcohol.

Alcohol evaporates much faster than water so the bowl should dry and stabilize much quicker than

a bowl placed in a paper bag and allowed to slow-dry.

Note: Lowes sells denatured alcohol for about $16.00 a gallon - a much better deal than the quarts sold at Walmart.

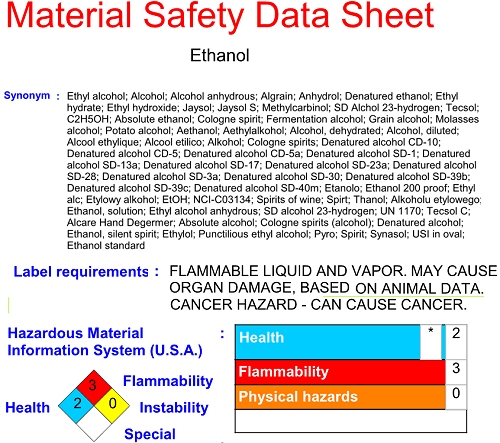

It's always worthwhile to review the MSDS (Material Safety Data Sheet) so you know the risks.

I suppose I should pick up some rubber gloves if I am going to be handling this with some regularity and it would be advisable to keep it away from open flame.

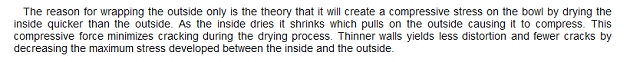

I decided to go ahead and hollow out a Hackberry round which came with tenon included.

MC for this round is around 16%

The tenon looks a little small for a piece this large but I'll give it a try.

I think I will be ok with tail stock support for a while...

So far so good. I think I can actually get two bowls out of this.

This is working well so far but it feels like I'm picking up a bit of a wobble.

............... sheared right off. I thought the tenon was on the small side.

The tenon, or lack thereof.

Plan B is a glue block. Problem with this is that I've turned off all the wax so the round is going to have to be kept moist for several days while the glue dries and since the blank has to be kept moist, the glue is probably going to take longer to dry. Always something............

Important Note:

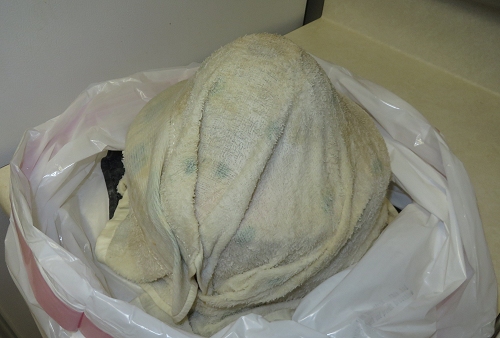

One should always set aside enough time when turning green wood, to finish it the same day it was started.

If this is not possible, wrapping the round in wet towels and then a plastic bag drawn tight over that usually works to prevent cracking.

I have had instances in the summer when working on large green pieces where cracks started to form in less than six hours with no protection.

Note: while the glue was drying on this one, I mounted another piece of hackberry with a smallish tenon. Didn't make it 5 minutes before shearing off. I think I will contact the vendor about the problem. It's not fun having big chunks of wood fly off the lathe at 500 rpm.

Keeping the round moist while trying to dry the glue is a bit of a challenge.

This is a method I sometimes use where I keep tail stock support for as long as possible when I don't trust the tenon or the wood is more dense in some areas than others.

The support piece is removed when ideal depth is achieved.

One pound, six ounces is the roughed out weight.

Moisture content is about 16% - not that bad.

Hmmm.... I think I might have to pick up a couple extra cans of Denatured Alcohol.

It's about 17 degrees outside and one theory is when water begins to freeze, it expands and becomes less dense and that would allow alcohol to more easily displace water in the wood. Sounds reasonable enough to me so outside it goes.

Soak time varies and it depends on wall thickness if you want to get particular. From what I've read, a 24 hours soak will cover just about anything I plan to do so that will be the SOP for the rest of these blanks.

Today's date is 12/15/2013

One day later, the weight is.....WHAT?.

Lets see, 2 Lb, 10.5 oz minus 1 lb, 6 oz equals 20.5 oz.

There are 32 ounces to a quart so that's almost three cups of alcohol that got soaked into the round.

That's also about three times the amount of Pentacryl used for one round.

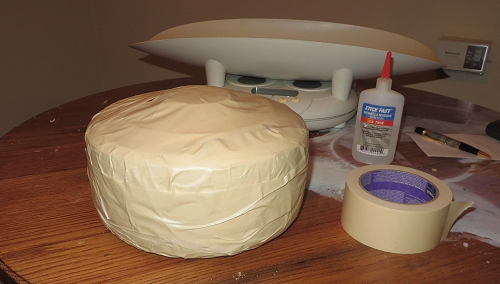

Several days later the round is dry enough to tape up. It is recommended that the blank dry upside down to further stabilize and slow the drying process.

Inset are a couple examples from another website where paper bags are used.

The completed Hackberry rounds 12/16/2013

The theory here is that if the inside of the bowl blank dries faster than the outside, drying stresses will be directed inward rather than outward and that will reduce cracks and warping.

Or put another way:

The original instructions used paper bags and masking tape.

Frankly, I think just masking tape will work better.

The bowl should be dry within 2-3 weeks. The first test is a sniff test. If the bowl smells of alcohol, it's not dry.

Occasional weighing and MC measurement with a meter will tell the tale.

Box Elder

Test case 2 is piece of Flame Box Elder which rumor has it, can be kind of punky. I have never worked with it

and have a little concern about the weight - almost 12 pounds. On a mini-lathe, that may be a bit extreme.

The guide will not even travel the full length. Oh, and no glue block for this - faceplate only.

That explains the 12 pounds. The piece has a MC of 24%, or about three pounds of water.

This will be the perfect candidate for the denatured alcohol bowl soaked test.

For a piece this heavy, I am going to want a large tenon and I can get away with one a little less than

three inches in diameter. I normally like using glue blocks better but not for this one - don't need any 12 lb hunks of wood flying off the lathe at 500 rpm.....

The piece is turning down quickly and the lathe is handling the piece well.

The tenon looks good and feels reasonably hard. Sometimes punky wood can make for an easily crushed tenon. This will be a nice looking bowl if it stays in one piece.

Still a solid 24% on the moisture content meter.

..........nice chunk of heartwood too..........

This chuck by the way, is the Barracuda brand.

For a lightweight chuck, it does a very good job and does not break the bank.

Any time I hollow out a questionable, off-center or heavy piece, I always keep tail stock support for as long as possible - learned that the hard way.

It takes a bit longer to hollow the bowl with the live center in the way but it is much safer.

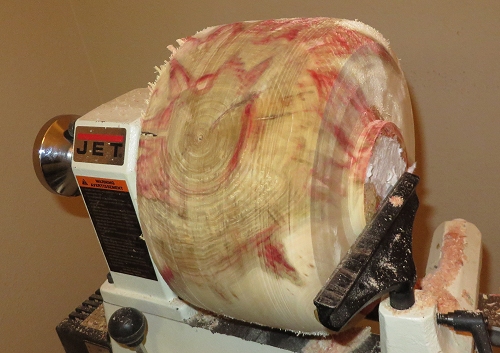

Well, that's about it for the night. Time to wrap things up ...........

Literally.

The bowl is covered with wet towels and then placed in a plastic bag to set for the night.

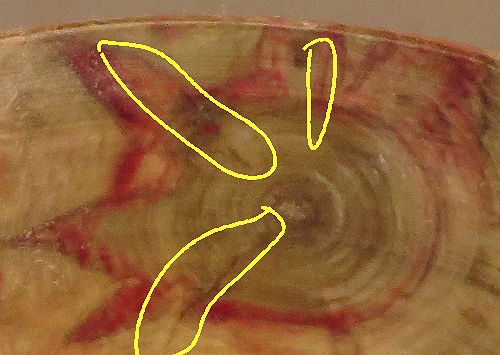

Heartwood cracks and splits easily and there is a lot of it in this bowl.

I'm thinking that after the denatured alcohol is completed and the bowl is dry enough, the existing heartwood cracks should all be covered with CA glue prior to being taped up.

End of day one - 12/17/2013

Day Two

It only takes another half hour or so to finish hollowing out the bowl.

The tail stock support made it pretty much to the bitter end.

Nice looking but there's a lot of heartwood there. The bowl blank now weighs 4 lb 1/2 oz

and the walls are about 3/4" thick.

That's about eight pounds of material removed from the round.

I think these cracks are going to have to be glued once the blank dries out from soaking.

Lowes is the only place around I could find that sells denatured alcohol by the gallon.

At $16.00 a gallon, that's much better than Walmart or Home Depot's quart-sized containers going for over $6.00 a quart.

Today I learned something I did not know about denatured alcohol - it does a wonderful job of removing finishes from work tables. This was of course originally a dining room table but since I never use it for that purpose, it now looks like a real work table.

Reminder to self: Next time, load up denatured alcohol in the sink and....get a bigger plastic container.

I'm going to let this piece set in alcohol for a couple days out on the deck.

1lb, 5 oz denatured alcohol soaked into the bowl.

This is going into a storage closet outside where the temp is about 30 degrees for the day, but first I need to practice a little crack control.

Ready for storage.

End Date - 12/20/2013

1/15/2014 - 23.7 - 24.4% Moisture Content - Switched to a better MC Meter.

I decided to soak the round in denatured alcohol again and I was storing this outside.

Either it did not get a lot of alcohol penetration or I left the walls too thick. We shall see.

Start date - 12/18/2013 Weight: 4lb, 5.5 oz

12/27/2013 - 3 lb , 1/2 oz

03/12/2014 - 2lb, 6 oz MC = 14.5

Spalted Maple

This is a 6 lb, 15.5 oz piece of spalted maple....

Spalted Maple

.....Another piece apparently fresh off the tree.

One thing about green wood - the chips are heavy and don't travel far at all. The plastic mat is about 42 X 60.

The chips are so wet, they stick to the Lexan shield.

That's 3 pounds, 12 ounces removed from the round.

The walls are around 3/4" and the piece was soaked over night.

This one only soaked in 3 ounces of alcohol, Good thing I kept the walls thicker.

It's now taped up and in storage. I hope it turns out ok - nice figuring in this maple round but there is a longitudinal crack in it......

12/22/2013 - 3lb, 6oz, MC = +24%

04/12/2014 - 2lb, 2.5oz, MC = 5 and change

04/16/2014

This piece of maple is ready to turn but there was about 1/4" of movement in the bowl as it dried and boy it would be nice to have some tailstock support.

I keep a few blanks around for creating tailstock support....

Works rather well!

This is one nice looking piece of wood and this is the first coating of Tru-Oil

Manzanita Burl

I've worked with Manzanita before, but never a burl - something a little different.

One reason I bought the piece was that it is reasonably symmetrical.

Taking it for a test spin, it is centered well enough.

Manzanita burl turns easily enough and it looks like there is some red in it - a bit less than expected for Manzanita.

The more I turn this, the whiter it gets...

I dunno about this one.....It looks like I'm turning any color the bowl has, out of the bowl.

It looks like that if anything, there might be some color on the inside and that's about it.

Fresh out of the alcohol soak, this burl looks like it has a bit of color after all. All is not lost!

All wrapped up and ready for storage. The burl absorbed about four ounces of denatured alcohol.

12/23/2013: 2lb, 9oz MC = 22%

04/12/2014: 1lb, 12.5oz MC = 12.8%

To be continued as the pieces dry..............

Overall Conclusion

As compared to drying using paper bags Denatured Alcohol is much faster. Pentacryl is somewhat faster than Denatured Alcohol and it also comes at a price......it is more expensive.

Pentacryl also can clog sanding disks:

Therefore, I think I will go with denatured alcohol in the future.

Link to Pentacryl Experiment.

Link to Downloadable Spreadsheet