Late in the summer I accumulated 25 or so green bowl blanks from various vendors off of Ebay, just about

all cut fresh off the tree and sealed using AnchorSeal or Paraffin.

The advantages in turning green wood are:

1. Cost - Price + Shipping is usually lower than buying a dry round (assuming you can find one).

2. Ease in turning - not as hard on the tools.

3. A lot less dust and if you are doing this in an apartment, this is a biggie.

The disadvantages of green wood are:

1. Warping

2. Checking

3. Splitting

4. Cracking

5. Shipping Costs

6. Drying Time

7. Storage Space

Helpful Buying Hint:

Buy your rounds in the fall as temperatures start to cool off. If stored outside the colder the weather gets, the slower the rounds lose moisture and the less likely they are to start cracking out.

Moisture Content (MC) frequently runs + 20% if you purchase one of these rounds, meaning that many of

these waxed and sealed pieces were quite literally freshly cut off the tree.

Waxed and sealed does not do a lot of good if the round contains heartwood or significant amounts of rot,

which is frequently hard to spot when looking at photos of a waxed round. It does not take long for these

rounds to start cracking regardless of how much sealant has been applied.

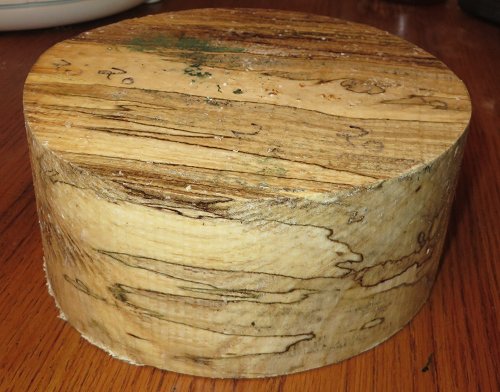

Here is an example:

This Hackberry round when presented on Ebay, looked fine. Nice color and spalt and about 22% MC, which was about 6% more MC than advertised.

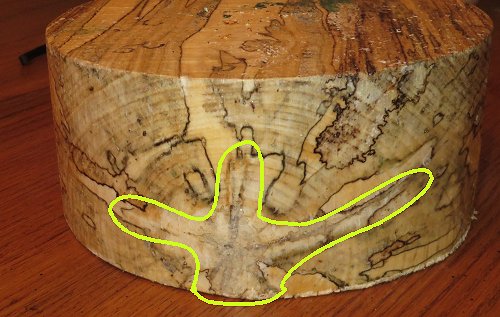

Turning the round 90 degrees reveals what wasn't shown - heartwood. How about the other side.....

How about that - more heartwood with some significant cracking. Funny how that wasn't shown on the Ebay pics either. However, I think most of this can be turned out and I also think I have another Pentacryl candidate.

To some Ebay vendors, a round is a round no matter from where it was cut. All they care about is the

final sale.

When buying waxed and sealed rounds off of Ebay, Caveat Emptor.

Rounds with heartwood are not good candidates for microwave drying and they usually cannot be stored for

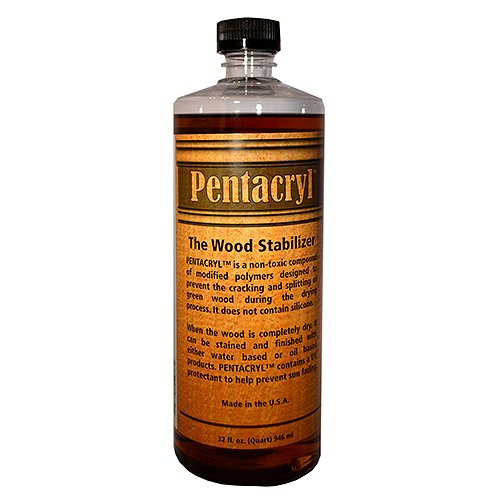

long periods of time without significant damage so today I am going to experiment with a wood stabilizer called Pentacryl.

I read about Pentacryl a couple months ago but could not find much detailed information about it, except

that it was on the expensive side and it worked. At @ $20.00 a quart, it had better work.

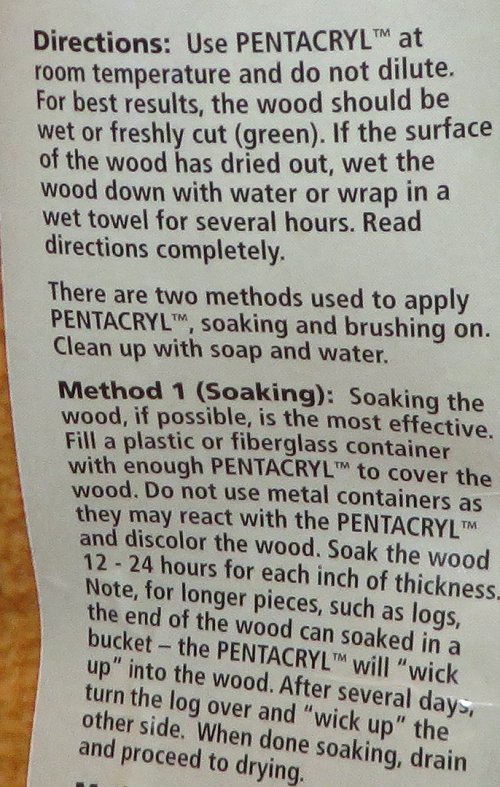

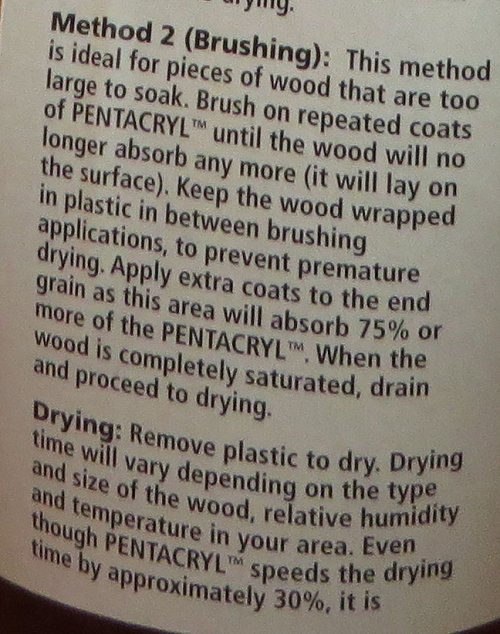

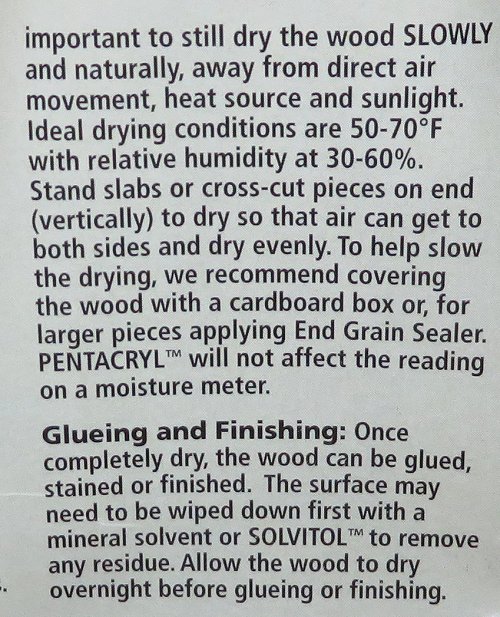

Here is the label information:

The directions seen straight forward enough - the part about green wood is not going to be a problem.

I don't have a plastic bowl but I do have a stainless one and that should work fine.

My experimental round is a piece of spalted hackberry which was purchased a couple months ago waxed and

sealed with a MC of 18%. I knew there was a section of rot but I did not notice the heart wood until the

round started cracking a couple weeks ago. I need to do something with this soon or I'm going to end up

with chunks only suitable for pen blanks.

The plan is to rough turn this to less than one inch wall thickness, take out the rot and as much heart

wood as possible, and soak in Pentacryl.

Hmmm.... the live center easily pushed in at least 1/4" into the round. That's probably not a good thing.

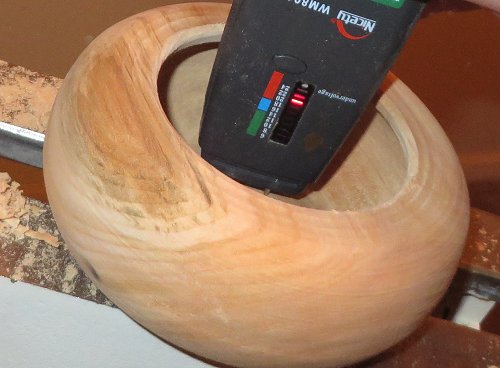

At turning time the hackberry round had a MC of 16-18%

Important Note:

One should always set aside enough time when turning green wood, to finish it the same day it was started.

If this is not possible, wrapping the round in wet towels and then a plastic bag drawn tight over that usually works to prevent cracking.

I have had instances in the summer when working on large green pieces where cracks started to form in less than six hours with no protection.

The 'Easy Rougher' with optional Lexan shield should get this trued up in a hurry.

The Lexan shield is not really an option unless you like taking sawdust showers.

The easy tools tend to kick chips back at you and the shield deflects the majority of chips back towards the workpiece.

The 'Easy Finisher' can be used in positions where conventional gouges cannot.

Here, the tool is being pushed and pulled horizontally across the piece from the side.

It's nice being able to make use of unconventional angles.

This piece of hackberry is looking really nice.

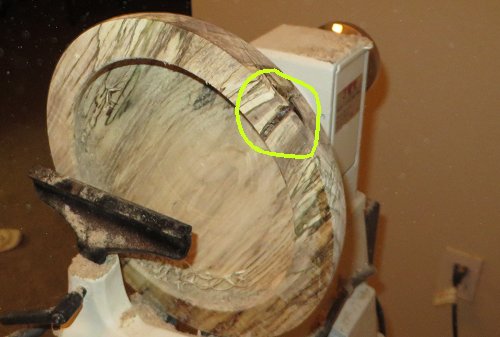

And this of course is the area that concerns me.

It is looking like most of the rot should turn out. I've found the finisher seems to work better than the rougher for hogging out bowls.

Under an inch was the plan so this is ok.

It is a good idea to leave the bowl top edge thicker when drying green wood because it gives you a better chance of ending up with a symmetrical product after drying, and there's extra to work with if it does warp a bit.

Start to finish in less than an hour and....no tool sharpening required!

This is not bad - only one small problem area and the cracks have been turned out.

Hope they stay that way.

Now for the interesting part..........

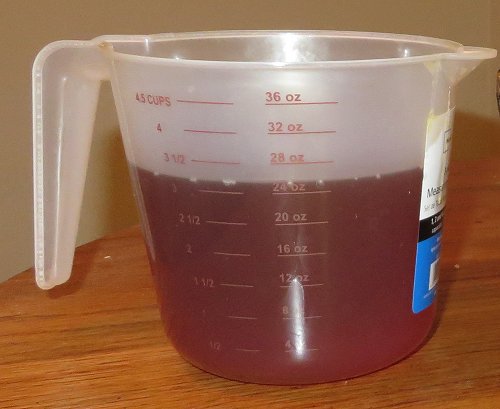

It looks like I could have used a bit more than a quart but this will work. Let it soak for 12 hours this way and then flip it over for another 12 hours.

24 hours later, I removed the piece and was curious to see how much Pentacryl had actually been absorbed.

Looks like the bowl sucked up about 3/4's of a cup, or bout 6 ounces..

The piece is going to look nice, assuming it holds together.

The piece as it looks one day later and an example of 'wicking' mentioned in the label instructions.

Out of curiosity I took a MC reading and the blank ranges from 14-18% (12/06/2013)

01-10-2014 - MC around 8% - Ready to turn.

01/20/2013 - Very little warpage or movement with this piece. Looks nice and is finished with Tru Oil

In the meantime, it would be wise to rough-turn the Hackberry piece which was somewhat deceptively advertised.

Upon closer examination, something else seems a little off here.........

Well how about that - green mold growing underneath the wax! On the other side, green mold was growing through the wax.

Boy, you really need some humidity and a high moisture content to achieve that....

Remember to remove the wax from the round before gluing, as glue does not stick very well to wax.

After thinking on it a bit, I decided to leave the heartwood on the bottom.

One thing about green wood - it sure is easy to turn.

It should be easy to turn - only 22% MC and a fine candidate for Pentacryl.

This one is going to be left at 3/4" wall thickness to see what if any difference there is in drying / warping as compared to 1/2" wall thickness.

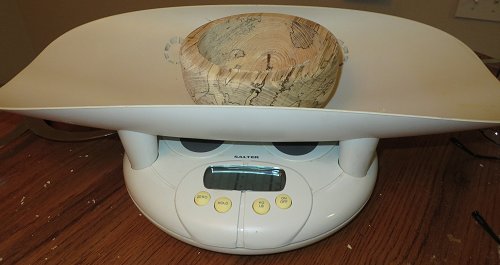

The rough-turned bowl weighs one pound, one and one half ounces. Might as well get more scientific.

By the way, this is a Salter Baby Scale and it works very well for weighing rounds.

One hour later, still 22%.

Now for the Pentacryl soak, which will go on for 24 hours.

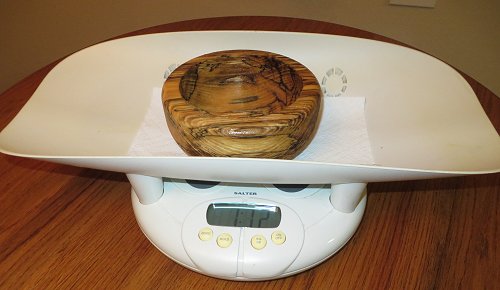

Before soaking, the round weighed 1lb 2.50 oz.

After the soak, the round weighs 1lb 12 oz.

That's about 9.5 ounces of Pentacryl that soaked into the round.

The date for this is 12/08/2013

About half the Pentacryl has been used on two blanks.

Next up is a piece of spalted apple. Might as well try Pentacryl on a couple different types of wood.

The apple is turning down rapidly and it has a MC of 22%.

This one I'll try at about 3/8" . I've worked with apple before and it is usually pretty stable.

The tenon on this one is being removed to use on a piece of cherry - the final round for the Pentacryl experiment.

12.5 ounces before dunking in Pentacryl.

Not much Pentacryl left. There should be enough for one or two more bowls.

The Pentacryl-soaked Apple bowl blank put on 4 1/2 ounces of weight, which worked out to about one cup of Pentacryl.

The way this is going, one quart of Pentacryl will probably handle four bowls of 8" in diameter or less, which works out to about $5.00 apiece - not very cost effective.

I think it might be worth it to try the denatured alcohol method after this exercise. I can get a quart of denatured alcohol from Walmart for about $6.00.

Started drying 12/10/2013

Finished 01-2014 using Tru Oil.

Last up in this exercise is a piece of cherry.

The meter says 16-18% but I suspect the MC is higher than that.

The cherry round is very easy to turn and the chips are fragrant - smells just like cherry/

3/8" is the final wall diameter, which might be a bit thin.

I thought so - 20-22% MC on the bowl inside.

12 ounces is the final weight prior to the Pentacryl soak.

I'm letting this one soak for a while. The wood is dense and green.

The cherry blank only soaked up one ounce of Pentacryl.

Started drying 12/12/2013

Bowl Complete! 01/17/2014

About five weeks, give or take. Not bad at all.

So, is Pentacryl Worth the Price?

Pros:

A. Pentacryl definitely speeds up the drying process.

B. Minor movement as the piece drys.

Cons:

A. Pentacryl residue in embedded in the turning round quickly clogs up power sanding disks.

The brown stuff on the disks is Pentacryl.

B. Wood texture as felt by finger tips seems a little off in some but not all finished pieces.

I doubt the average end-buyer of one of these pieces would be able to discern a difference.

I think a person experienced in wood finishing probably would.

Conclusion

As compared to drying using the paper bag or denatured alcohol techniques, Pentacryl dries wood faster.

However, denatured alcohol is a whole lot cheaper and it speeds the drying process admirably. I do not feel that odd difference in wood texture that I sometimes feel using pentacryl, when using denatured alcohol.

Denatured alcohol has the added bonus in that it does not clog sanding disks.

Therefore, I think I will go with denatured alcohol in the future.

Link to Denatured Alcohol Experiment.

Link to Downloadable Spreadsheet